- CNC Routing

- CNC Routers - Fully Portable

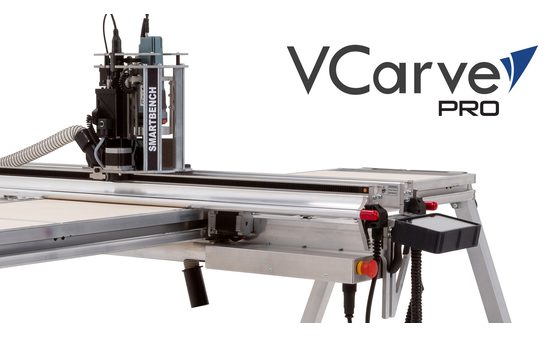

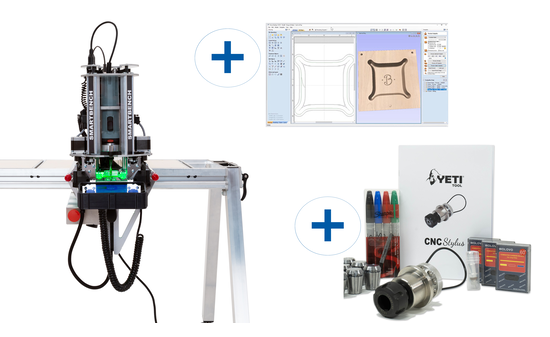

- YetiTool SmartBench

- CNC SmartBench Precision Pro Plus

CNC Router SmartBench Precision Pro Plus

The world's first CNC machine with autonomous speed adjustment

With the YetiPilot V1.0, our partner YetiTool has created the world's first CNC milling machine with autonomous speed adjustment! The machine monitors the power consumption of the milling spindle in real time in 200ms cycles and automatically adjusts and increases or decreases the feed rate in such a way that the machine is automatically operated in its optimal working range.

Delivery time 1-2 days

EUR 9,881.80 *

Delivery time 1-2 days

EUR 10,255.29

EUR 9,947.63 *

Delivery time 1-2 days

EUR 10,680.80

EUR 10,360.40 *

Delivery time 1-2 days

EUR 10,994.79

EUR 10,664.95 *

Delivery time 30 working days

EUR 1,049.00 *

Delivery time 1-2 days

EUR 373.49 *

Delivery time 1-2 days

EUR 799.00 *

Delivery time 1-2 days

EUR 966.54 *

Advantages of the CNC machine SmartBench Precision Pro Plus thanks to YetiPilotV1.0

Time saving

- Reduce the learning curve: spend your valuable time on your projects rather than worrying about feedrate, speed and infeed.

- Optimisation of the machining strategy: Thanks to the automatic monitoring and control, your projects can be produced faster than would be possible with a purely manual setting.

Cost savings

- Reduction of job losses: Milled workpieces due to incorrect cutting values (feed, speed, infeed) are a thing of the past with the YetiPilot V1.0 CNC milling machine. The most common problems with incorrectly milled workpieces result from incorrect cutting data. Excessive traversing speeds lead to step losses in the stepper motors and from then on only the emergency stop can help. Since YetiPilot V1.0 constantly operates the machine in the optimal power range, step losses are virtually eliminated.

- Adjusting the brush life: The load on the milling spindle has a direct influence on the life of the carbon brushes. Here, too, operation in the optimum working range protects the carbon brushes and prolongs their life.