- Routing

- Router Bits

- 8 mm Router Bits

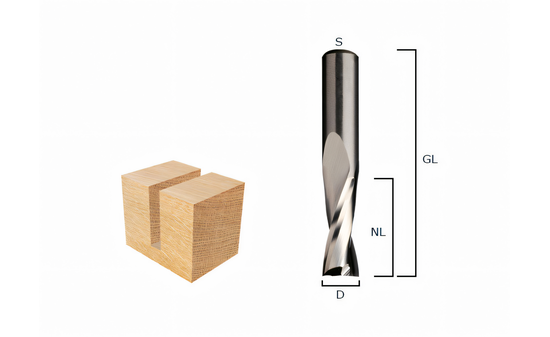

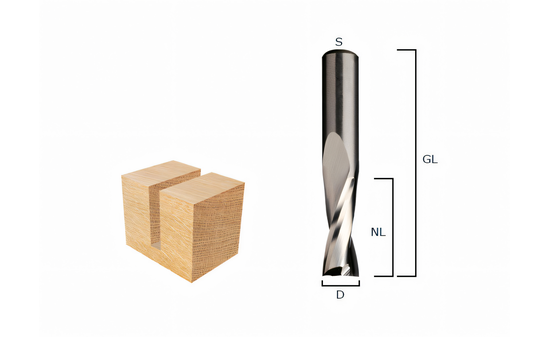

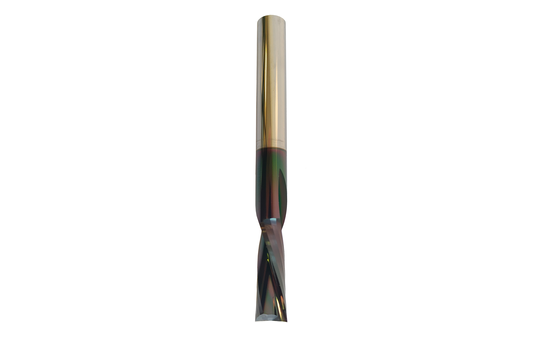

- Spiral groove cutter

Spiral Groove Cutter 8 mm

Spiral groove cutters are suitable for processing all types of wood, such as softwood, hardwood, as well as all wood and board materials. Also Plastic can be routed with the router at an appropriately regulated speed. They are also ideal for the use in CNC routing. Furthermore, these routing cutters are also excellent for immersion, i.e. also for recesses and drilling.

Advantages of spiral routing cutters

- the cut is uniform and therefore clean

- reduces vibrations

- pulling speed is increased during routing

Delivery time 1-2 days

EUR 44.32 *

Delivery time 1-2 days

EUR 58.26 *

Delivery time 1-2 days

EUR 44.32 *

Delivery time 1-2 days

EUR 58.26 *

Delivery time 1-2 days

EUR 44.32 *

Delivery time 1-2 days

EUR 44.32 *

Delivery time 1-2 days

EUR 58.26 *

Delivery time 1-2 days

EUR 43.53 *

Delivery time 1-2 days

EUR 43.53 *

Delivery time 1-2 days

EUR 44.24 *

Delivery time 1-2 days

EUR 44.24 *

Delivery time 1-2 days

EUR 61.51 *

Delivery time 1-2 days

EUR 60.55 *

Delivery time 1-2 days

EUR 60.55 *

Delivery time 1-2 days

EUR 87.36 *

Delivery time 1-2 days

EUR 94.94 *

Delivery time 1-2 days

EUR 58.74 *

Delivery time 1-2 days

EUR 89.00 *

Delivery time 1-2 days

EUR 74.03 *

Delivery time 1-2 days

EUR 89.00 *

Delivery time 1-2 days

EUR 101.03 *

Delivery time 1-2 days

EUR 48.86 *

Delivery time 1-2 days

EUR 93.21 *

Delivery time 1-2 days

EUR 48.86 *

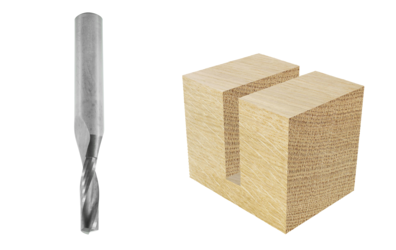

Difference between right- and left-hand twist

Depending on the application and machine, please note whether you require a spiral grooving cutter with right-hand twist/right-hand rotation or left-hand twist/left-hand rotation.

A right-hand twist, also called an "up-cut", is recommended for fast work. Here the chips are ejected immediately and clogging is avoided. The result is also a very clean groove bottom.

Spiral groove cutters with left-hand twist, "Down-Cut", on the other hand, work with a pulling cut and produce an enormously clean cutting edge and are therefore ideally suited for use where the Edges remain visible afterwards. Disadvantages are the chip removal downwards, a not so clean groove bottom and the slower feed speed.