- Drilling & Screws

- Wood Drills

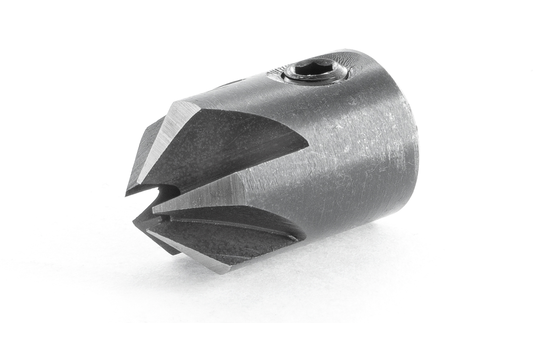

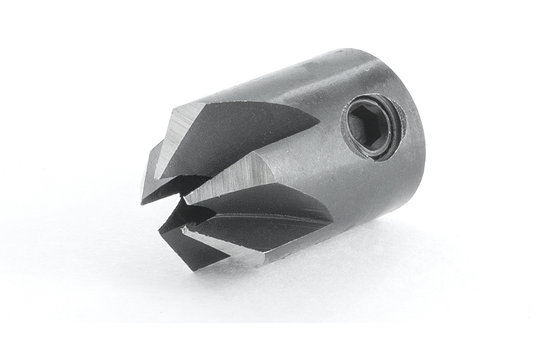

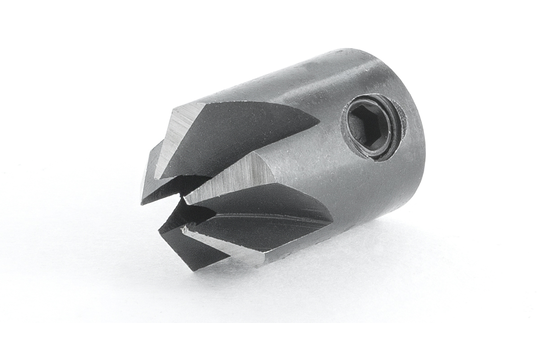

- Countersinks & Countersink Drills

Wood Drills

Countersinks & Countersink Drills