- Drilling & Screws

- Wood Drills

- Countersinks & Countersink Drills

- Countersinks

- Cross Hole Countersink

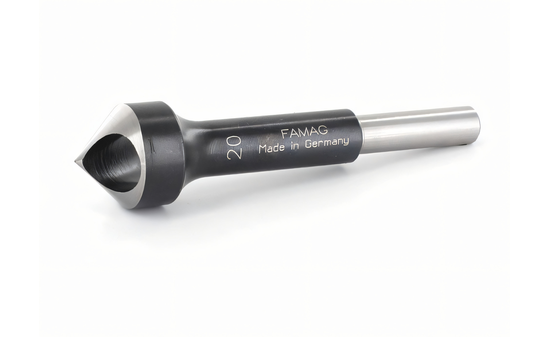

Cross Hole Countersink 90°

In the cross countersink, the cut is not made with one or more straight cutting edges, as is the case with the taper or rim countersink. Instead, the head of the tool is drilled so that a circular cutting edge is produced. This cuts both clockwise and counterclockwise, making the chamfers of the countersink particularly smooth.

Delivery time 1-2 days

EUR 25.12 *

Delivery time 1-2 days

EUR 28.80 *

Delivery time 1-2 days

EUR 33.74 *

LONG TOOL LIFE AND HIGH CUTTING QUALITY

The cross hole also contributes to a significantly better chip ejection. The chips are ejected upwards and therefore do not jam so quickly in the countersink. This also contributes to a higher quality of work. In addition, the better chip ejection ensures faster work and a longer tool life.

The high quality of Famag's German production and the precise grinding also ensure a significantly improved cutting result.

These advantages are offset by the higher price compared to simple countersinks and rim countersinks.