The workbence is the center of the workshop.

Working with hand tools

Workbench

The most important tool of the traditional carpenter and joiner is and remains the workbench. Almost all work with the classic hand tools, e.g. saw, plane, chisel, is carried out on this workbench. It offers the necessary conditions for this: The work surface is level to be able to work precisely and solid to be able to withstand heavier loads. As a rule, this is a heavy, strong bench top made of solid wood. The base frame of the workbench is also usually a heavy and stable solid wood construction, for example, to absorb the shear forces that can occur during planing. A base cabinet or tipping drawer is often inserted into this base frame to accommodate frequently used tools, aids and materials.

To facilitate working with hand and power tools, the workbench has a number of clamping options for the workpieces: It is equipped with one or two work vices. Holes are drilled in the bench top, the bench clamps, sometimes also on the front of the frame, to insert bench dogs or clamps to fix the workpiece. In this way, the workbench becomes the woodworker's "third hand".

Sawhorses

Another classic aid used by carpenters and joiners for various manual tasks are sawhorses. They are mainly used as a supplementary support for the workbench for larger workpieces and as a substitute for the workbench for work that can easily lead to damage (sawing) or soiling (surface treatment) of the workbench.

Lifting table

Surface treatment and final assembly of tall or large workpieces often require a work surface that is significantly lower than the top of the workbench or another workstation. In such cases, the use of a lifting table is a good idea, as it makes it possible to adjust the desired working height to suit the work to be carried out.

Mobile workbench and clamping table

In the workshop, but especially on the construction site, you will appreciate the advantages of a mobile workbench or clamping table. Often these aids are equipped with holes for bench dogs and with adjustable clamping jaws and thus represent a mobile variant of the workbench without offering its high load capacity. On the other hand, on the construction site, many jobs with hand tools or power tools cannot be carried out with the necessary precision without a workbench of some kind. But also in the workshop you will quickly learn to appreciate the additional work surface and clamping possibilities, especially when the workbench is needed for other work.

Working with power tools

Multifunctional Tables (MTF)

Basically, different demands are made on a workbench if you mainly work on it with power tools. However, it must fulfil two functions just like the workbench: It must provide a support surface for the workpieces, and it must be possible to fix the workpieces for machining. When working with power tools, the multifunctional table therefore shows its advantages.

A perforated worktop usually rests on a metal or aluminium base frame and accommodates accessories such as bench dogs, so that you can also clamp irregularly shaped workpieces. In addition, clamps of all kinds can be attached to a base frame made of system profiles,, in order to hold the workpiece. this offers the possibility of attaching fixtures to the multifunction table, which is usually not so easy with a workbench.

We offer a wide selection of ready-configured multifunction tables. However, you can also assemble everything necessary from our range to build a workbench yourself according to your particular wishes and requirements. In terms of size and working height, there are no limits. Our multifunctional table configurator is invaluable when it comes to putting it together.

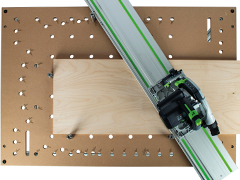

Our Vario-Bench multifunctional table shows its strengths especially when cutting materials with a hand-held circular saw, but not only there. The special arrangement of the holes in the worktop allows precise sawing at any desired angle.

If you want to create your own completely individual working area on the multifunction table, take a closer look at the Vario-Master MFT template. It combines the intelligent perforated grid of the Vario-Bench and is also a template for creating your very own multifunction table. A wide range of accessories contribute to the unlimited variety of applications.

Router table

In addition to the typical multifunctional table, which lives up to its name thanks to its high flexibility, there are also work tables for use with certain power tools. First and foremost is the router table:

In many woodworking shops, the router table serves as a solution and alternative to the fixed bench router. A router or router motor (recommended) is used as the drive unit, which allows full use to be made of the variety of cutters. The router table offers different guides, safety devices, extraction connections and adjustment options. As with the multifunctional tables, we also offer you the option of choosing between ready-made solutions, configurable models and tables that you build yourself entirely according to your own ideas.

To help you, we have developed our router table configurator, which supports you in putting together your individual and compatable router table.

Working on fixed machines

Working trestles and roller trestles

An essential component of fixed woodworking machines - circular table saw, band saw, table router, planer and thicknesser, pillar drills - is the integrated work table. Often there are two tables:an input and an output table, for example, in the case of planing machines or circular table saws. However, work on such machines can often be made easier and more precise by using suitable additional tables. Especially work trestles and roller trestles are often almost indispensable as additional aids when processing large workpieces in order to be able to feed and remove the material safely. This is especially true when you are working alone.

Mobile machine base

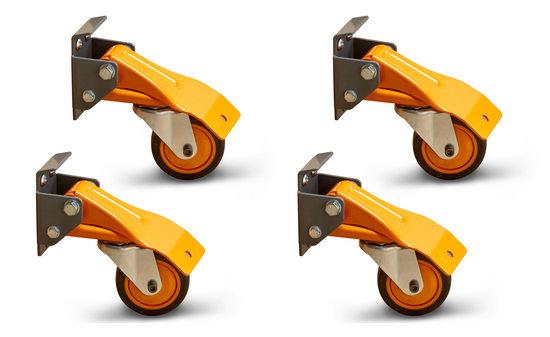

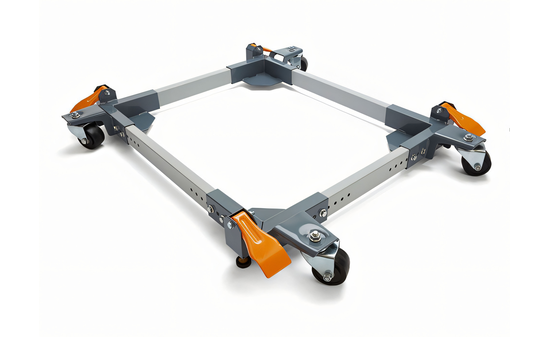

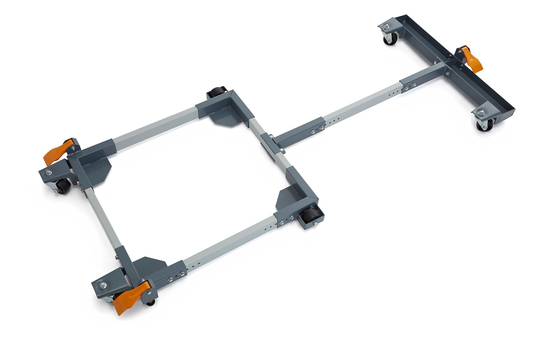

In smaller workshops, not all fixed machines have to be set up ready for work at all times. Often there is also the possibility to put them on wheels together with their base frame and only roll them into the room when you need them. A mobile machine base is ideal for this. We offer a very flexible mobile machine base from Bora that can carry up to 680 kg

Bora Portacube Mitre saw base

Cross-cut and mitre saws are often used for cutting very long workpieces. The Bora Portacube mitre saw base is an alternative to support tables made in-house and to mobile work trestles. It not only serves as a base and work table, but also enables the saw to be transported safely and easily.