- Routing

- Router Bits

- 8 mm Router Bits

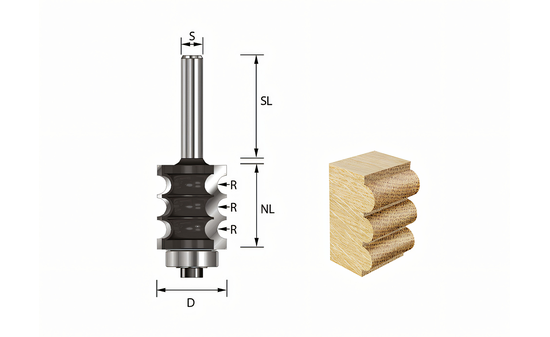

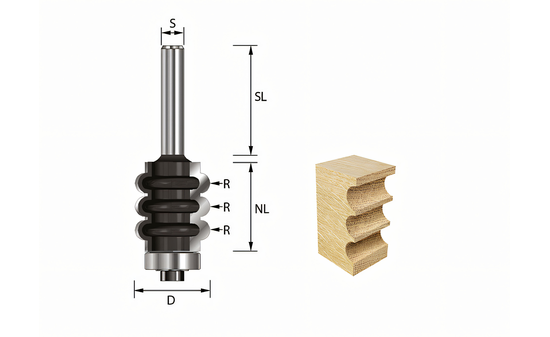

- Profile cutters

- Decorative Moulding Cutter

Decorative Moulding Cutter 8mm

Delivery time 1-2 days

Article no.: E-15450

EUR 71.33

incl. 19% VAT

Delivery time 1-2 days

Article no.: E-14850

EUR 92.87

incl. 19% VAT

Delivery time 3-10 days

Article no.: E-14860

EUR 92.87

incl. 19% VAT

Delivery time 3-10 days

Article no.: E-15520

EUR 100.71

incl. 19% VAT