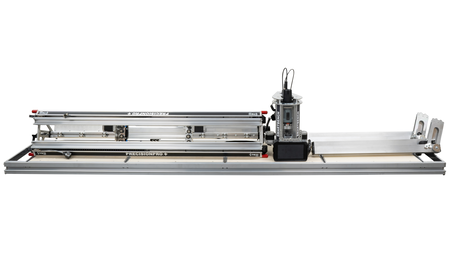

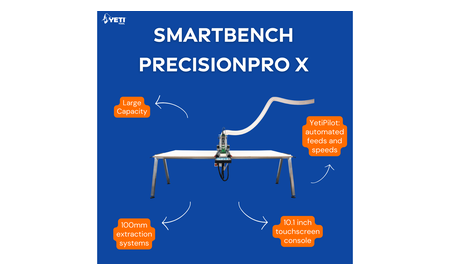

CNC milling machine SmartBench PRECISION PRO X from YetiTool Version 1.3

Perfect results even without CNC experience thanks to YetiPilot 1.0

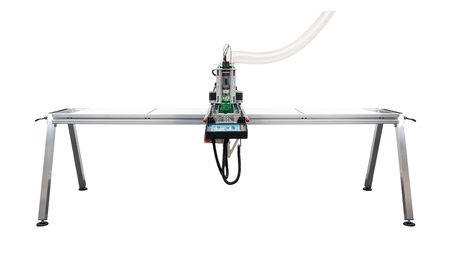

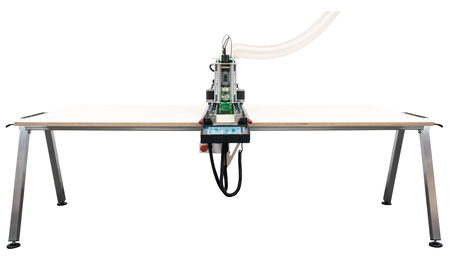

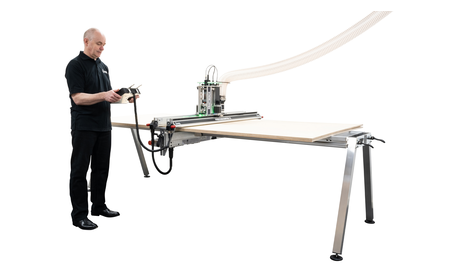

The SmartBench from YetiTool is not just a mobile CNC router, but the professional and fully-fledged answer for joineries with limited space and for all private woodworkers who are enthusiastic about an efficient and easy-to-use CNC solution. The SmartBench can be set up in 3:00 minutes and is immediately ready for use. The CNC router can be dismantled and stowed away in the same time. A real innovation for professional requirements without compromises.

The world's first router with autonomous speed adjustment - YetiPilot V1.0

With the YetiPilot V1.0, our partner YetiTool has created the first CNC router with autonomous speed adjustment! The machine monitors the power consumption of the milling spindle in real time in 200 ms cycles and automatically adjusts and increases or decreases the feed rate so that the machine is automatically operated in its optimum working range. But it's not just the machine that benefits from YetiPilot V1.0 - there are also massive advantages for you as a user:

Time savings

Reduction of the learning curve: Spend your valuable time on your projects rather than worrying about feed rate, speed and infeed.

Optimisation of the machining strategy: Thanks to automatic monitoring and control, your projects can be produced faster than would be possible with purely manual settings.

Cost savings

Reduction of job losses: Milled workpieces due to incorrect cutting values (feed, speed, infeed) are a thing of the past with YetiPilot V1.0. The most common problems with incorrectly milled workpieces result from incorrect cutting data. Travelling speeds that are too high lead to step losses in the stepper motors and from then on, only the emergency stop will help. As YetiPilot V1.0 constantly operates the machine in the optimum power range, step losses are virtually eliminated. This saves you money with YetiPilot!

Adjustment of the brush service life: The load on the milling spindle has a direct influence on the service life of the carbon brushes. Here too, operation in the optimum working range protects the carbon brushes and prolongs their service life.

YetiPilot V1.0 works for...

- Milling cutters with a diameter of 3mm - 10mm

- contour and pocket milling cutters

- a predefined list of materials

- Constantly being developed and expanded.

Features and advantages

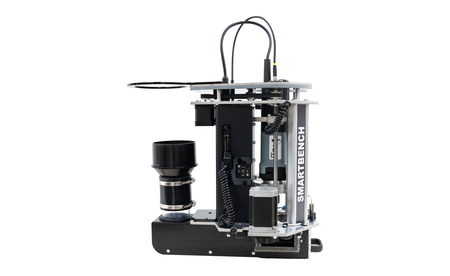

YetiTool SC2 router motor - the digital solution for your SmartBench

The YetiTool SC2 milling motor - made by Mafell - is equipped with a precision mount for ER collets (ER16) and thus ensures enormous concentricity . The digital control electronics cyclically send speed and load data to the SmartBench at 200 ms intervals, which are analysed by the SmartBench. The SmartBench then adjusts accordingly.

- 1,000W YetiTool SC2 milling motor - made by Mafell

- Runs 22% cooler and 5% quieter than comparable motors

- ER16 system with collets from 1 mm - 10 mm (8 mm collet included)

- automatic speed control via the milling file

- Speed: 5,000 - 25,000 rpm

- Guaranteed concentricity of 0.01 mm

- SmartControl: Milling motor automatically provides feedback on the current load to the CNC control unit

- Real-time indication of the current motor overload in the display

- Automatic emergency stop if the milling motor is overloaded

Advantages & features

- Intuitive operation via colour touch pad

- Simple data transfer of the G-code via WLAN or USB stick

- Button (Z-axis) for quick, easy and precise adjustment of the Z-axis zero point

- Laser cross for precise determination of the X/Y zero point

- Assembly and disassembly of the complete CNC machine in 3:00 minutes each

- Regular free software updates to expand the functionalities (milling apps)

Drive & working area

- X-axis:

- Machining width: 1250 mm

- Maximum workpiece width: 1340 mm

- Maximum speed: 6,000 mm/min

- Zang bar gearbox

- Y-axis:

- Machining length: 2500 mm

- Maximum workpiece length: unlimited

- Maximum speed: 6,000 mm/min

- Rack and pinion gearbox

- Z-axis

- Machining depth: 152 mm

- Maximum material thickness: 152 mm

- Maximum speed: 2,000 mm/min

- Threaded spindle on both sides

Console

- Larger surface for easier use - coloured 10.1" touch pad

- App library ready

- Additional screen protection

- Robust housing

- Slim design

- 2 USB ports

- Easy SD card replacement

Software

- 3D CAD/CAM software (recommended):

- Vectric VCarce Pro: Further information can be found here

- Fusion 360: German videos can be found here

- ESTLCAM: German videos can be found here

- File format: .nc or .gcode

- CNC controller: GRBL

Extraction - BigFoot

- 100mm suction connection for extraction systems

- Integrated suction hose with connection for stationary suction systems

- min. 4200 l/min volume flow. Some materials may require a higher volume flow.

- max. 2,900W. More powerful extraction systems must be connected and switched on separately.

- permanently positioned extraction shoe independent of the milling motor position ensures optimum extraction results

- with new status light for better monitoring

- The use of the BigFoot provides capacity for larger tools.

Materials

- Softwood and hardwood up to 152 mm material thickness

- Plywood panels such as multiplex, blockboard etc.

- All types of wood-based materials (chipboard coated/uncoated, MDF etc.)

- Solid surface materials such as Corian, Staron, Hi-Macs etc.

- Plastics and acrylic glass

- Aluminium sheet

- Rubber (without abrasive additives)

- Maximum load (with evenly distributed load): 100 kg

Guarantee, safety and service

- Emergency stop switch

- Emergency stop bars on the X-axles

- The current job can be continued once the collision has been rectified

- Safety switch for milling unit

- 12-month warranty on parts and labour (excluding wear parts)